Here at MiTek we understand that integration is key to efficient construction, whether that be integration of people, software, design or products. Around the world MiTek’s strategy is to help our customers and business partners achieve that integration through innovation, support and world class solutions to the ever growing need for integrated 3D building design, as outlined for the UK in the Government’s own MMC strategy.

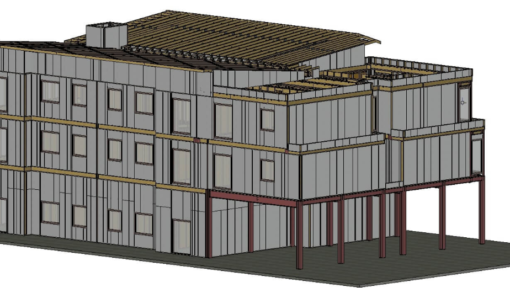

The successfully completed Henver Road project, in which MiTek assisted Frame Homes UK successfully deliver a complex 3 storey Timber Frame building featuring Posi-Joist cassette floors, roof trusses and steel frame is a great example of that integration in action.

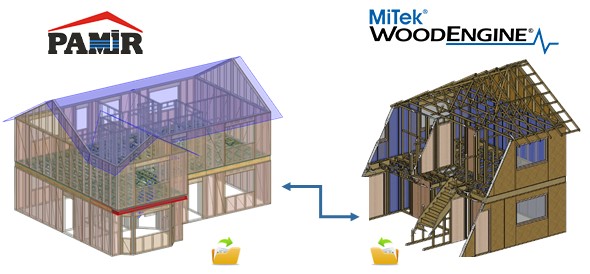

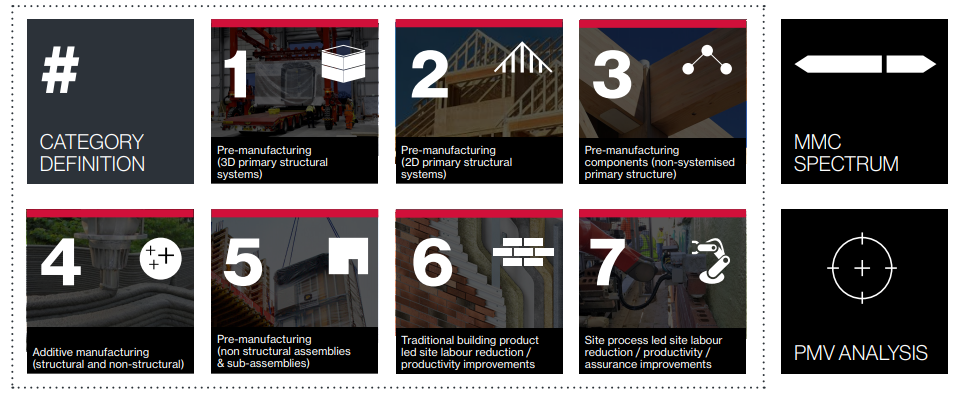

MiTek’s WoodEngine timber frame detailing software was used in conjunction with MiTek PAMIR timber engineering software as the main design products for integrating these elements, giving the structure a strong Category 2 rating on the UK government’s MMC Spectrum:

“We at MiTek recognise that MMC represents the future of UK construction”

Richard George – Managing Director

The Project

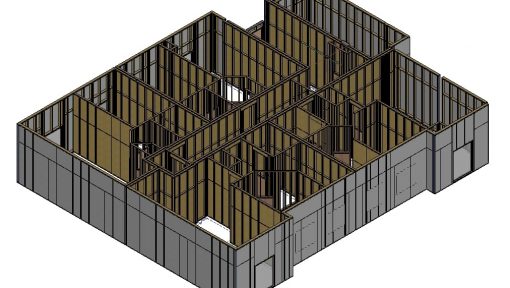

Henver Road is a 3 Storey Timber Frame apartment building in Newquay, Cornwall, with the structure supplied and manufactured by Frame Homes UK.

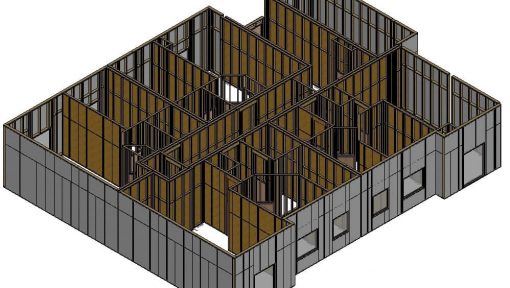

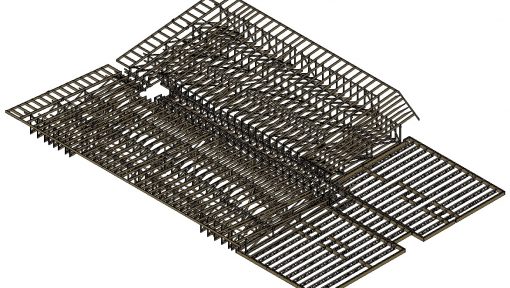

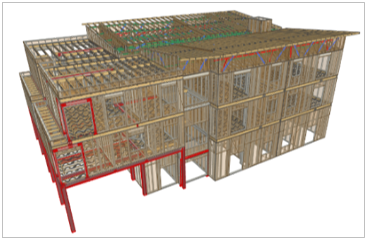

This was a complex build, requiring heavy structural integration of the main timber frame, Posi-Joist cassette floors, trussed rafter based roof structure, and steel frame elements, and was therefore an ideal candidate to showcase the power of MiTek WoodEngine timber frame software. An interactive 3D model of the complete building can be viewed here using any smartphone of computer.

software

This project provided an ideal chance to utilise recently developed tools enabling slick integration between MiTek’s market leading Timber Frame framing software, WoodEngine, and MiTek’s market leading Timber Engineering software, PAMIR.

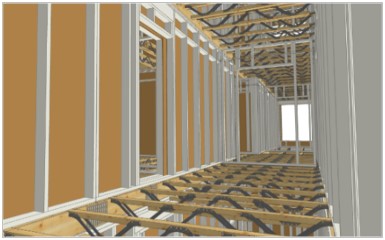

A simple file is transferred from one package to the other. Importing the WoodEngine file into PAMIR automatically creates 3D walls (with stud positions shown), adds structural openings (stairwells, SVPs and Roof Lights) and creates steel beams and columns, giving the truss and Posi-Joist designer a huge head start, and more importantly eliminating the possibility for input error. Sections and notes can also be brought through to PAMIR making communication between timber frame and floor/roof designer easy, whether they sit within the same business or are transferring data between seperate companies.

Once the floor or roof design is done a single button press creates a file to send the Posi-Joist and roof design back into WoodEngine. The WoodEngine model is updated instantly to show exact locations of all members and webs, and 3D joist hangers are also brought through to complete a fully accurate 3D model.

If changes are made to either the WoodEngine or PAMIR designs the link file can simply be updated, and the imported file is updated dynamically, with no need to delete the original import file.

The link proved invaluable in this project, with Reece Brookes focussing on the timber frame design in WoodEngine, and Tobiasz Kazanowski concentrating on the Posi-Joist floor cassettes in PAMIR. The link meant that it was simple to identify any potential issues, and the transfer of walls and steel components between the packages was a huge timesaver and avoided elements having to be drawn twice.

Kurt Rutherford co-ordinated things from the Frame Homes side, and now makes full use of the WoodEngine-PAMIR link on all of his projects.

“ We use the Pamir – WoodEngine link to create all house 3D models for checking and customer review, this method saves a lot of time compared with 2D model checks & helps identify potential issues which otherwise would have gone unnoticed. I find the link works really well and renders beautifully.”

Kurt Rutherford - Frame Homes UK

The Team

Working with our partner Frame Homes, MiTek identified this project as an excellent opportunity to develop the skills of our apprentice Reece Brookes, who was studying a 2 year apprenticeship studying for a L3 Construction in the Built Environment qualification. Reece took on the role of lead timber frame designer, and also spent time on the factory floor to understand the processes required for high quality and consistent panel manufacture.

Reece has now completed his apprenticeship and has become a full time member of MiTek’s WoodEngine support team.

“The Henver Road Project was a vital part of my development as an apprentice, the opportunity to design a timber frame building using BIM and watch it be manufactured from start to finish taught me a variety of skills that I use on a daily basis since the project completion.”

Reece Brookes

MiTek understands that support is vital to the solutions we provide the UK construction industry. To support Reece in designing this project, our Graham Daniels, Justin Bishop and Tobiasz Kazanowski provided their extensive experience to guide Reece through the design process.

Graham Daniels, who has 15 years at MiTek and 22 years in the offsite construction industry continues to lead the MMC team at MiTek.

To further strengthen the team Gary Pickford, who has been with MiTek for 2 years in a technical support role, will have an increased focus on MMC and in particular our WoodEngine software. Gary has a range of experience gained over 20 years working in technical and commercial roles for roof truss and timber frame manufacturers, and brings a lot of knowledge and energy to the team.

We are also delighted to announce the appointment of Andy Bryant as Technical Support Manager. Andy joins us having worked for a leading off-site manufacturer, holding multiple roles throughout design, production/logistics and management and brings to MiTek a wealth of knowledge of the timber frame industry, and in particular production and business management processes.

We are confident that these changes strengthen our team and will help us as we support our customers and adapt to the changing needs of the industry.

“The opportunity to join MiTek and help them develop their MMC capabilities utilising our key offerings of Software, Automation, Engineered Products and Design Services, was very exciting. MiTek is a world-leading global company that can share knowledge and experience to deliver solutions to specific problems and I am relishing the challenge of working with existing and new customers to build better, expanding on their current capabilities, allowing them freedom to do things they couldn’t before and helping customers be more successful”

Andy Bryant, Technical Support Manager

The project was a great success, with the design, manufacture and construction of a very complex project all completed without issue thanks to the integration and interoperability between the MiTek software packages.

“When we visited site we were delighted to see construction progressing well with no issues in taking the complete 3D digital model of the structure and translating it to the practical elements of construction.”

Graham Daniels – Head of CAD Systems.

Reece Brookes was subsequently nominated for Apprentice of the Year at the G4C Construction Excellence Awards, in large part due to his involvement in this successful project.

If you have a project that you feel could benefit from our expertise, or are struggling to find solutions for consistent construction issues, please contact us at [email protected] and a member of our Business Development Team will be happy to discuss the solutions we can offer.

Find out more

Find out what benefits MiTek can bring to your business today, get in touch below.

Email us