MiTek customers are now getting deeper sustainability insights, spread across more of our products’ lifecycles. Learn about the new, improved environmental standards we’re embracing.

In 2024, people want to see hard proof that you’re building sustainably. For years, solutions like our Posi-Joists and Connector Plates have provided hard evidence of their green credentials. That’s because we opt into voluntary EU transparency standards.

The standards have been expanded and we’re proud to say that so has our commitment to them. That means more tangible evidence for specifiers and customers to make informed decisions, and to demonstrate they’re doing the right thing.

Jimmy Close, UK Business Development Director, explains: “With sustainability, our customers are making huge strides forward and need the data to collaborate across the supply chain and to make informed choices about the products they specify.

“By committing to these higher European standards, we’re giving them more of the critical data that drives decision-making. How sustainable is Component A compared to Component B, across its full service life? Well, now you can put some solid numbers behind that comparison.

“The next step is integrating these standards into our industry leading software platform, PAMIR, cutting even more friction out of the comparison process. We’re very excited about this next step and how it will continue to help customers and specifiers make critical decisions, particularly with the FHS and the journey towards a net zero future.”

What’s new with EN 15804+A2?

Our Posi-Joist and Connector Plate solutions have been Environmental Product Declarations (EPD) verified in the UK since 2022. EPD documents are a voluntary way to quantify a construction product’s environmental impact using life cycle assessment (LCA) data.

Knowing exactly how green each component is, gives the supply chain expanded insight, letting them plan more effectively and work more sustainably. Since 2012, EPDs have been governed by EU standard EN 15804.

EN 15804 and its first amendment (A1) covered a product’s impact from cradle to gate. More recently, a second amendment (A2) was introduced to track environmental impact from cradle to grave.

To let you enjoy maximum possible transparency, we’ve expanded our EPDs to meet A2 standards.

EN 15804 A1 vs A2: What’s different?

The data required by A1 covered the pre-construction stages of a product’s life. It included the raw materials being used, along with how the product gets manufactured and transported.

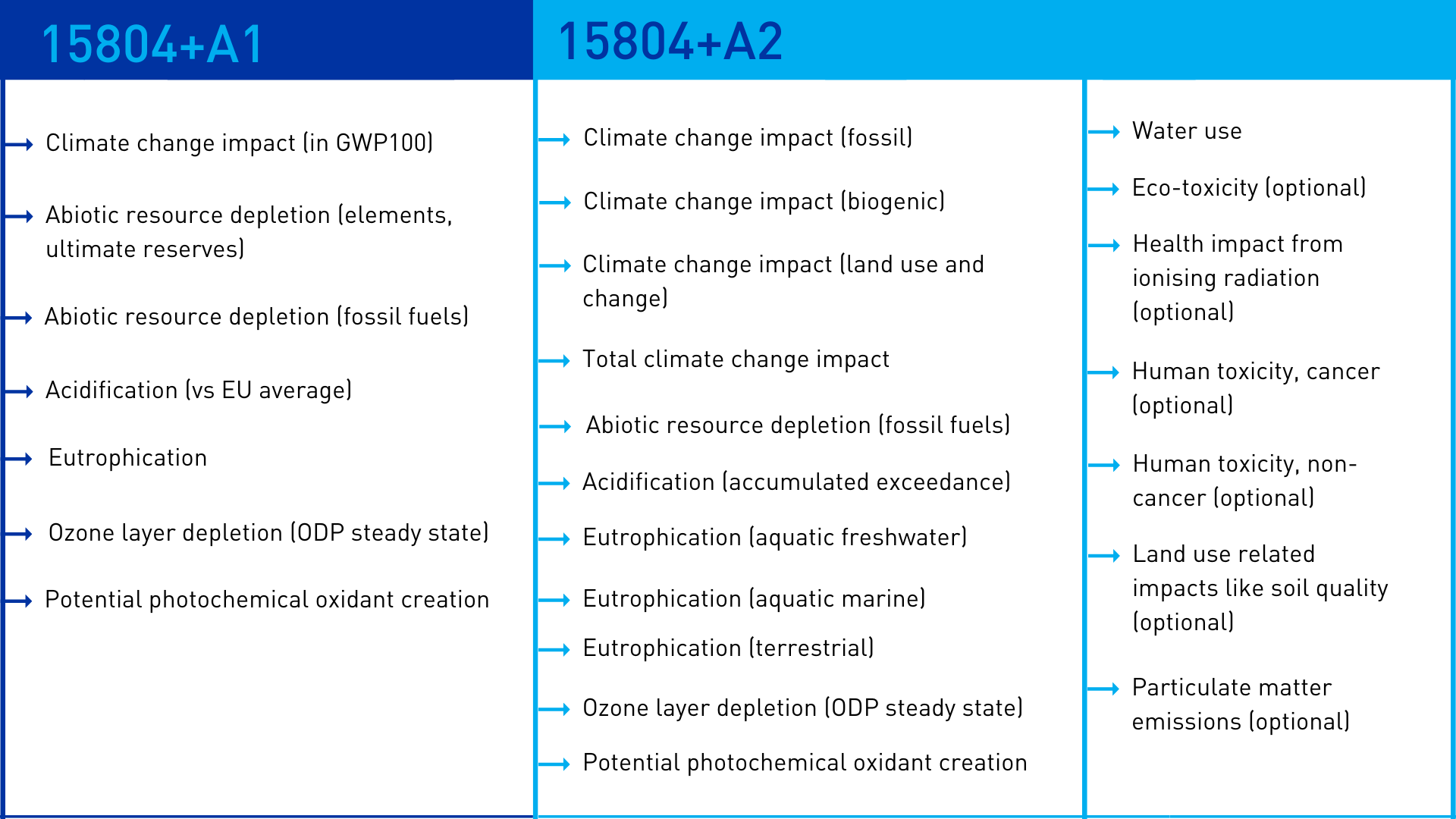

A2’s data requirements are significantly expanded. They cover:

- The product’s actual use in construction: how it’s delivered to site and installed

- Active service life: its use, maintenance, repair, replacement, or refurbishment, along with its operational energy and water demands (if applicable)

- The end-of-life stage: how the product is deconstructed or demolished, transported away, then processed or otherwise disposed of

Specifically, A2 looks at more individual impact categories than A1:

Greener supply chains build brighter futures

We’re committed to giving our customers the information they need to make optimised choices. If you’d like to learn more about our products like Posi-Joist and their sustainability credentials you can find the full EDP details here.

To view the EPD’s click here or visit Greenbook Live, or the ECO Platform, where results are publicly listed in Europe. They are also hosted in BRE’s LINA portal for people to download.

More info

What does an EPD contain?

The EPD contains information about the product and its potential environmental impacts and benefits:

- Technical information: Relevant product data and information

- LCA information: Environmental impacts, e.g. Global Warming Potential, Cumulative Energy Demand, Acidification Potential, but also a description of the LCA process (data, methods, assumptions)

- Other relevant environmental information (e.g. VOCs, hazardous materials, etc.)

- Review and verification information: Information on the LCA consultant and the EPD program operator, and the external 3rd party EPD verifier

The EPD enables specifiers to quantifiably demonstrate the environmental performance of a product, while Lifecycle Assessment is used to total up the environmental impact of a products supply chain.

EPD are an incredibly important industry marker of a products environmental impact, and more specifically its GWP (Global Warming Potential), which a products performance is ultimately scored on. The scope covers everything from raw materials supply, to transport, and manufacturing.

About BRE

BRE Global is internationally recognised for its expertise in LCA and pioneering work in the environmental evaluation of construction products for whole building assessment and other related schemes (BREEAM, The Green Guide to Specification, IMPACT, etc.).